Fly ash for concrete? Most concrete is formulated from water, broken stone or gravel, sand, and cement—generally Portland cement. The formulation can include a small quantity of waste material.

Fly ash is one such waste material. It offers three advantages. It reduces the need to dispose of some of earth’s abundant fly ash waste, it decreases cost, and decreases helps decrease damage to the environment.

What is Fly Ash?

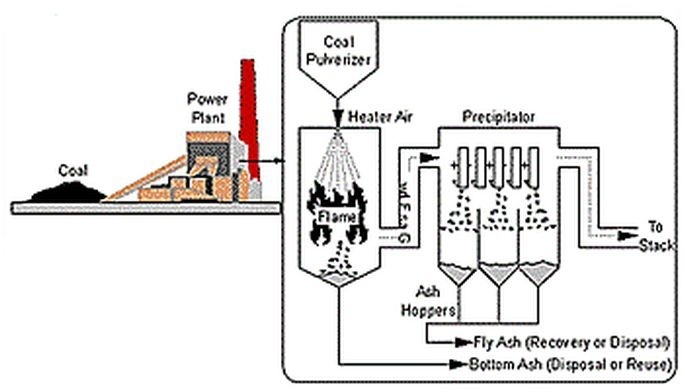

Fly ash is the lightweight particulate carried along by flue gases produced from burning coal in boilers. It may be removed electrostatic precipitation.

Although coal is mostly carbon, coal deposits are embedded in rock. Thus, inevitably, burning coal yields some silica (SiO2), alumina (Al₂2O3), and calcium oxide (CaO). Tragically, fly ash may be concentrated in arsenic, lead, and other substances.

Fly Ash – A Raw Material

Interestingly, some fly ash can be added as a substitute for some of the Portland cement component of concrete. Portland cement manufacture requires heating raw materials and driving off a large amount of carbon dioxide gas. In fact, for 1 pound of cement made an outrageous 3/4-pound of CO2 results! Check it out!

What does fly ash have to do with this? Fly ash consists of oxides and not carbonates. Using concrete formulas with 10% fly ash reduces carbon dioxide emission by an equal 10% as well. Further research into fly ash in concrete formulas is ongoing. Of necessity, because there is such an abundance of fly ash, other channels for its safe use continue to be explored.

Note: You might also enjoy Cement Production Aggravates Carbon Dioxide Levels

References:

- SlideShare: Fly Ash Concrete – A Qualitative Approach by Manish Kumar Mandal

- U.S. Dept. of Transportation: Federal Highway Administration: Fly Ash Facts for Highway Engineers

- The Virginian-Pilot: As fly ash piles up, the challenge for safe disposal rises