Some years ago, some made the claim that genuine chocolate isn’t ‘good for you’. They made the claim that artificial chocolate made from carob beans is superior. Curiously, so-called dog chocolate was already made from carob…

Thank goodness, science now concedes that chocolate is not all that bad; most of us can eat and enjoy at least some chocolate.

And now that we know it’s OK to eat chocolate – and it may even be good for us – did you ever wonder: How do we make cocoa from cacao, and what is the chemistry behind this treat?

Chocolate Chemistry: The Cacao Bean

The fruit pod of the Theobroma cacao tree has a tough rind encasing pulp as well as some 20 to 50 beans. The beans are typically white to violet in color before they are exposed to air and sun.

The part of the pod we want is the bean without its papery skin; to get to the cacao bean, manufacturers remove the rind and heap up the pulp and seeds to them to ferment.

Naturally-occurring fungi (Geotrichum & Candida) enables the fermentation of the pulp sugars (notably glucose, fructose and sucrose) into acetic acid, which improves the beans by killing the embryo within the seed plus imparting flavor and reducing bitterness.

The fermentation process also liquefies the pulp. The 6 carbon glucose and fructose sugars are fermented via the pathway,

C6H12O6 → C2H5OH → CH3COOH

Very similarly, the 12 carbon sucrose sugar is fermented via the pathway,

C12H22O11 → C2H5OH → CH₃COOH

That may look a little simpler if you look at it like this:

Sugar –> Ethyl alcohol –> Acetic acid

For simplicity, we don’t list the byproduct CO2 (carbon dioxide), as it is not of particular importance to the end result achieved by the fermentation. The manufacturer then removes the beans, dries them (in the sun or in ovens) and ship them off to factories for further processing or packaging.

Cacao Beans: Roasting and Skin Removal

Manufacturers roast the Cacao (Cocoa) beans, and remove the thin shell mechanically by a process called ‘winnowing’. Skin removal is a simple process, as can be seen in the video below, which demonstrates removal by hand.

In addition to taking off the skins, mechanical winnowing breaks the beans into small pieces called ‘nibs.’ Interestingly, during the fermentation process, the fungus kills the embryo of the seed by converting sugars within the pulp into acetic acid.

Chocolate makers remove this most volatile acid by roasting the beans. The process of removing volatile acids – those acids that largely boil away during the roasting process – affects flavor in chocolate, just as roasting changes the flavor of coffee.

Since there are some 400 to 500 chemicals making up the flavor of chocolate, it is difficult to provide a profile of flavor. However, there among the varieties of flavor-producers are alcohols, aldehydes, esters, ethers, furans, ketones, pyrazines and thiazoles.

Processing Cacao Nibs

Chocolate-makers first grind the cacao nibs into a paste called chocolate liquor. They can then separate this liquor into two components — cocoa powder and cocoa butter.

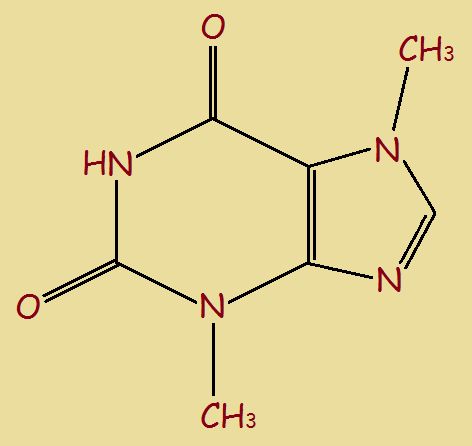

Cocoa powder (not the same as cocoa powder sold in grocery stores) contains the alkaloid theobromine — which possesses stimulative properties, but which is milder than caffeine. Cocoa powder also contains polyphenols. But what is an alkaloid?

An alkaloid is any of a group of nitrogenous organic compounds found in plants that have pronounced physiological actions on humans. Famous examples include: morphine, atropine and strychnine.

The word polyphenol indicates the joining of many phenol rings (C6H5OH) connected to each other. Polyphenols are prevalent in tea, red wine, coffee and olives, and are antioxidants, esteemed for health benefits.

However, those benefits may be partly offset if an abundance of other ingredients is present, for example dairy (creamer) and excessive sugar.

Cocoa butter is an edible fat or triglyceride of palmitic, stearic and oleic long-chain fatty acids.

Palmitic and stearic acids are saturated, whereas oleic acid is monounsaturated. Cocoa butter is very stable, with a low melting point.

Chemistry of Chocolate

We may process cocoa powder in a number of ways, including by alkali-treatment (Dutch chocolate), and may use it separately, or combined with refined cocoa butter and other substances, to form a variety of chocolate products for baking, candies and syrups. However we process the cacao bean, if we want the result to be chocolate, there’s going to be chemistry involved.

Note: You might also enjoy What is Carrageenan?

References:

- Crozier, Stephen, et al. Cacao seeds are a … (2011). Chemistry Central Journal

- Austin Community College: Bacteria in Food Production. (2012)

- University of Wisconsin: The Chocolate Tree – The Secret Ingredient. (2007)

- Jinap, Selamat, et al.: Effect of Roasting on Acidic Characteristics of Cocoa Beans. (1990). University of California San Francisco

- Clegg, Brian, et al.: Theobromine. Royal Society of Chemistry

- University of Michigan Integrative Medicine: Healing Foods Pyramid: Dark Chocolate. (2014)

- Afoakwa, E.O. , et al.: Changes in acidification, sugars and mineral composition of cocoa pulp during fermentation of pulp pre-conditioned cocoa (Theobroma cacao) beans. (2012). International Food Research Journal

- Summers, V.: The Chocolate Alkaloid Theobromine. (2016). QuirkyScience

← Back to Food and Health

← Home